core ROOMS

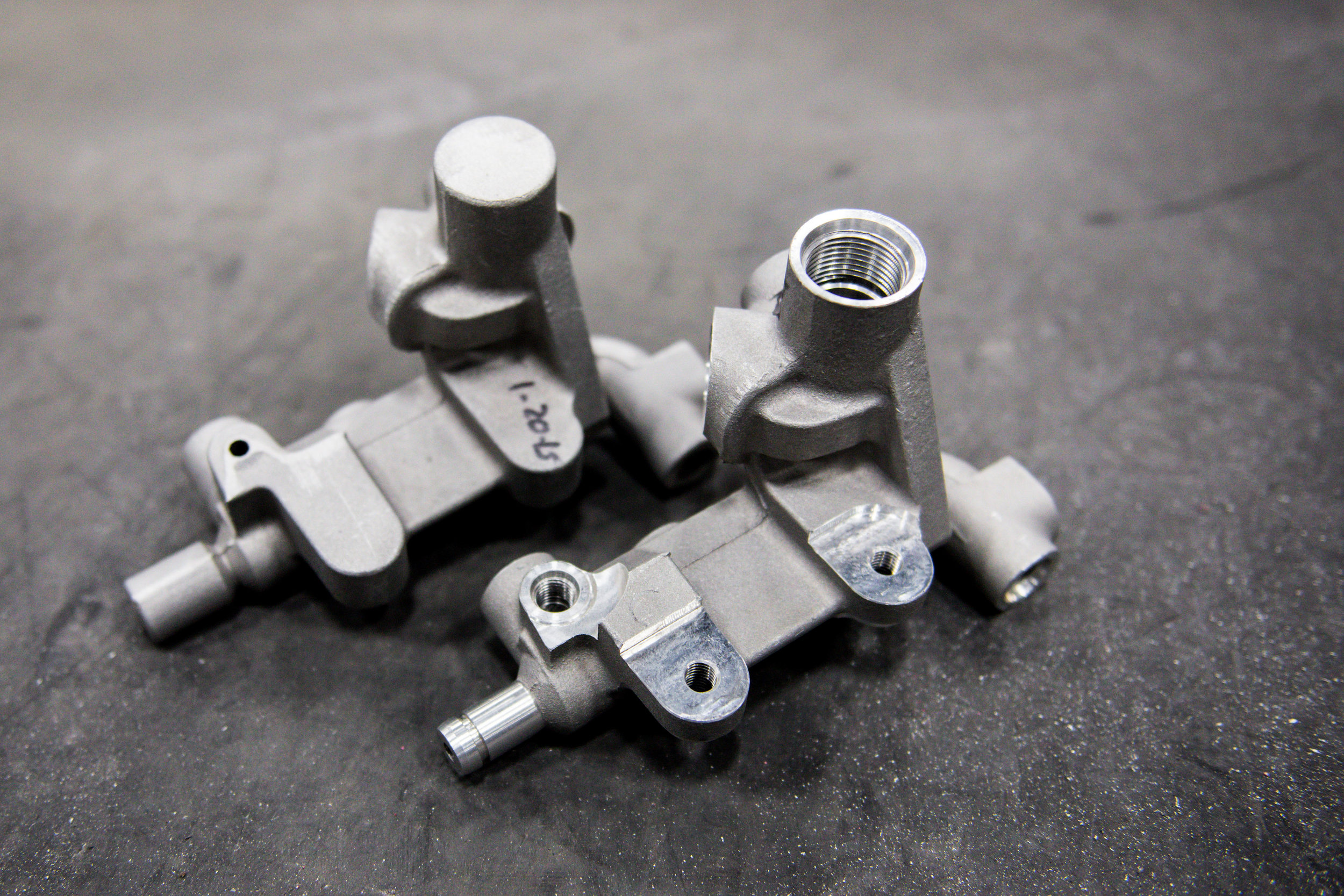

core manufacturing CAPABILITIES

Most castings start with a core. Our experienced core department is capable of producing cores of various size, shape, and complexity. We have the ability to manufacture cores with conventional shell core manufacturing or No Bake molding. Our shell core machine list consists of:

Dependable 100SA, 200SA, 400SA

Redford HS12, HS14, HS16

Shalco U180

No Bake core technology allows us to make cores outside the size restraints of a conventional machine, providing larger flexibility in design and production. No Bake core production is powered by a Tinker Omega PLC controlled mixer with output of 750 lbs/min.